-

nahtlose Rohre des legierten Stahls

-

Kesselstahlrohr

-

Hitzebeständiges Edelstahl-Rohr

-

Schweißender Hals-Flansch

-

Blinde Rohr-Flansche

-

geschmiedete Stahlflansche

-

Lap Joint-Flansch

-

EN1092 Flansch

-

Slip-on-Plattenflansch

-

Nickel-Legierungs-Rohr

-

Stumpfnaht Armaturen

-

geschmiedete Formstücke

-

Edelstahlverschraubungen

-

Incoloy-Rohr

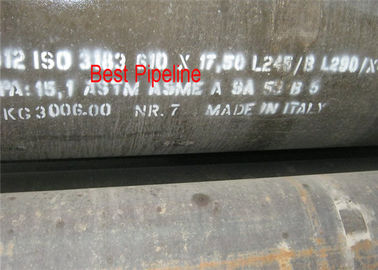

EN 10208-2; L415MB spiral welded pipes in Pipe Size :508 NACE MR0175 PSL2 Production Year :2018

| Herkunftsort | China |

|---|---|

| Markenname | Best |

| Zertifizierung | API /CE / ISO /TUV |

| Modellnummer | 1/2“ -48“ |

| Min Bestellmenge | 1 TONNEN |

| Preis | 450 USD/TON |

| Verpackung Informationen | 1) Im Bündel mit Streifen; 2) streifen erste Verpackung durch Plastiktasche dann ab; Die Details, |

| Lieferzeit | Versendet in 25 Tage nach Zahlung |

| Zahlungsbedingungen | L / C, T / T |

| Versorgungsmaterial-Fähigkeit | 100000 TON/YEAR |

Kontaktieren Sie mich für kostenlose Proben und Gutscheine.

WhatsApp:0086 18588475571

WeChat: 0086 18588475571

Skype-Anwendung: sales10@aixton.com

Wenn Sie irgendein Interesse haben, leisten wir 24-stündige Online-Hilfe.

x| Standard | API/ASTM | Grad | ASTM A252 Gr1/Gr2/Gr3 |

|---|---|---|---|

| Technik | SAW/UOE | Fertig stellen | entblößt |

| Schlüsselwort | Geschweißte Stahlrohrrohre | Inspektion | Mit hydraulischer Prüfung |

| Oberfläche | Gepanzertes /Painting/3PE | ||

| Markieren | black steel pipe,spiral welded steel pipe |

||

Dimensional standards

EN 10220:2002 “Seamless and welded steel tubes - General tables of dimensions and masses per unit length”

ISO 4200:1989 “Plain-end steel tubes, welded and seamless”

CSN 42 5738:1979 “Spiral weld steel pipes”

DIN 2458:1981 “Welded steel tubes”

EN 10219-2:1997 “Cold formed welded structural hollow sections of non-alloy and fine grain steels”

API Spec 5L:2004 “Specification for Line Pipe”

GOST 8696:1974 “Electrically welded steel pipes with spiral seam”

PN 79/H-74244:1979 “Welded steel pipes for transportation of media”

Technical delivery regulations

CSN 42 0144:1979 “Spiral weld steel”

DIN 1615:1984 “Welded circular tubes of non-alloy steels without special quality requirements”

DIN 1626:1984 “Welded circular tubes of non-alloy steels with special quality requirements”

CSN EN 10208-1:2000 “Steel tubes for pipeline for combustible liquids” - part 1: Requirements according to class A

CSN EN 10208-2:1999 “Steel tubes for pipeline for combustible liquids” - part 2: Requirements according to class B

DIN 17120:1984 “Welded circular tubes of non-alloy steels for steel constructions”

DIN 17172:1978 “Steel tubes for pipeline for transport of combustible liquids and gases”

DIN 1628:1984 “Welded circular tubes of non-alloy steels with very high quality requirements”

CSN EN 10217-1:2003/A1:2005 “Welded steel pipes for pressure purposes”

CSN EN 10217-5:2005/A1:2005 “Submerged arc welded non-alloy and alloy steel tubes with specified elevated temperature properties”

EN 10219-1:1997 “Cold formed welded structural hollow sections of non-alloy and fine grain steels”

API Spec 5L:2004 “Specification for Line Pipe”

GOST 8696:1974 “Electrically welded steel pipes with spiral seam”

PN 79/H-74244:1979 “Welded steel pipes for transportation of media”

| Name | SSAW/Spiral Welded steel pipes |

| 2.Standard |

API5L, ASTMA252, ASTMA139, ASMEB36.10,AWWAC200, EN10217,EN10219,EN10224,EN10025; SY/T5037,SY/T5040,GB/T9711.1/9711.2,API 5L, GB/T3091 Anticorrosive coating:AWWAC205,AWWAC210,AWWAC222,AWWAC214 |

| 3.Outer Diameter | 219-3048mm |

| 4.Wall Thickness | 5mm—30mm |

| 5.Length | 6m,12m or as per customer's requirements |

| 6.Packing | In bulk |

| 7.Payment Term | T/T, L/C at sight |

| 8.Delivery Time | within 20-40 days after receipt of deposit or irrevocable L/C at sight |

| 9.Delivery condition |

Beveled or Plain end with varnish/2PP/2PE/3PE/3PP anticorrosive coating as per clients confirmation ; With or without protecting caps as per customer's requirements;with FBE internal coating for water steel pipes. |

| 10.Material | A53(A,B),Q235B,Q345B,16Mn, 20#,S235JR, S355JR;ASTMA252 Gr.2,Gr.3; ST37,ST42,ST52;Gr.B,X42,X46,X52,X56,X60,X65,X70, etc |

| 11.Usage | for petroleum/ natural gas pipeline , for conveying water,drainage,coal gas, mineral slurry and other low-middle pressure liquids. Also for chemical industry, building structure,heat-supply and pile driving projects. |

| 12. Export to | Canada, USA, Argentina,Peru, Chile, Colombia, Brazil, Venezuela,Malaysia, Singapore, the Czech Republic, Australia, Myanmar, Kenya, South Africa, Spain, Italy, France, England, the Netherlands,Belgium, etc |

| 13.Certificates | API 5L; ISO9001:2008;ISO14001:2004; OHSAS18001:1999 |

Packaging Details

1) In bundle with strip;

2) First packing by plastic bag then strip;

Details packing please see the picture in the detial description.

3) In bulk

4)Client" requirements

Delivery:

1)Container:

25 tons/container for pipe with usual outer diameter.

For 20" container the max length is 5.8m;

For 40" container the max length is 11.8m.

2) Bulk carrier:

It is no requirements to the length of the pipe. But its booking space time is long.

.Coating Standard:

ANSI/AWWA C104/A21.4 American National Standard for Cement-Mortar Lining for Ductile-Iron Pipe and Fittings for Water ISO 21809 Petroleum and natural gas industries -- External coatings for buried or submerged pipelines used in pipeline transportation systems DIN 30670 Polyethylene coatings of steel pipes and fittings

.End:

square ends (straight cut, saw cut, and torch cut). or beveled for welding, beveled

.Surface:

Lightly oiled, Hot dip galvanized, Electro galvanized, Black, Bare, Varnish coating/Anti rust oil, Protective Coatings (Coal Tar Epoxy,? Fusion Bond Epoxy, 3-layers PE)

.Application:

It products are widely applied to water, sewage, gas, air,heating steam and low pressure liquid transportation pipes, wire casing, scaffolding , fire use for metal structural.

Product Show

![]()

![]()

Material :

![]()

Specification :

![]()

Production Line

![]()

![]()

Testing :

![]()